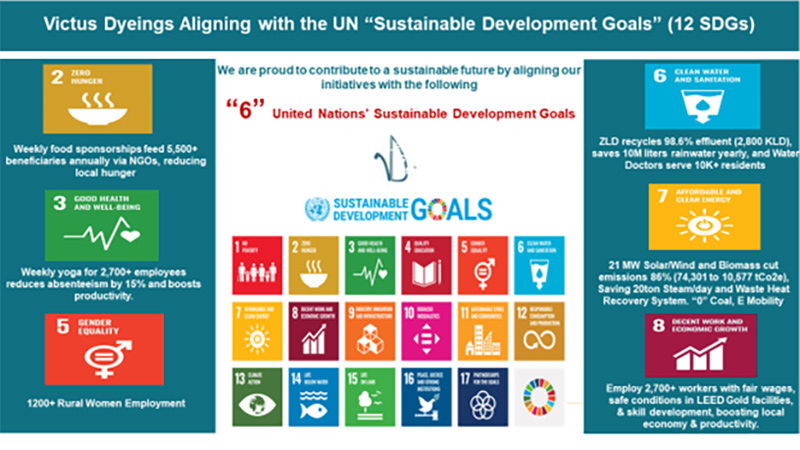

Creating Value Responsibly — For People, Planet, and Progress

At Victus Dyeings, sustainability is a strategic imperative. We believe that true progress balances environmental stewardship, social responsibility, and ethical governance across every stage of our textile value chain.

Our vision is built on four pillars:

For us, sustainability means creating long-term value by respecting people and nature — while driving innovation and accountability in how we operate.

Economic Sustainability:

To actively contribute to the broader economics we operate through job creations, financial contribution and exemplary corporate behaviour to ensure that we can earn our license to operate in all our markets.

Social Sustainability:

To operate in a growing economy where Victus is an integral enabler helping to provide secure live hoods and activity participate in the communities in all our markets.

Environmental Sustainability:

To maximise the reduction, reuse, and recycling of materials and non –renewable resources we use in our business to product the nature environment for future generations.

I Trust that the sustainability report for 2021 provides new insights into the Victus Dyeings roles, activities and sustainability impacts I can assure our Stakeholders that sustainability has been elevated to a new level importance in Victus and that board oversight is vigilant.

Sustainability

Water Stewardship & Wastewater Innovation

At Victus Dyeings, responsible water management is core to our sustainability strategy. As a water-intensive industry, we have adopted closed-loop systems and cutting-edge technologies to conserve, treat, and reuse water — aligning with Zero Liquid Discharge (ZLD) norms and global best practices.

Our Key Initiatives:

- Zero Liquid Discharge Achieved:

- 2800 KLD ZLD plant capacity

- 98.5% of treated water is recycled and reused in production

- Salt Recovery & Water Reuse:

- Salt recovery systems in place for reuse in dyeing processes

- Multiple Effect Evaporator (MEE) plant operational to recover usable water

- Advanced Monitoring & Recovery:

- Fully automated digital monitoring system for real-time performance tracking

- Condensate recovery systems & WHR installed — enabling reuse of thermal energy and reducing freshwater dependency

- Sewage Treatment & Reuse:

- 100% of treated STP water (Garment Divisions) is reused for irrigation and toilet flushing

Our closed-loop water system reflects our commitment to circular resource use, local water resilience, and climate adaptation.

Sustainable Product Commitment

Designing with purpose. Sourcing with responsibility.

Sustainable Raw Materials

Recycled & Circular Inputs

Eco-Friendly

Packaging

Low-impact Dyes & Finishes

Certified for Trust & Transparency

Clean Energy & Decarbonization

We are committed to the Science Based Targets initiative (SBTi) and actively contributes to global climate goals.

Renewable & Low-Carbon Energy Highlights

Energy Recovery & Efficiency Measures

Smart Monitoring, Optimization & Digital Sustainability Intelligence

Waste Management

Driving the circular economy through innovation and responsibility.

Chemical Management

Certificates

Environmental Certificates

GOTS

GRS

OCS

RCS

OEKO TEX

ISO 14001:2015

HIGG FEM

BCI

Reverse Resource Tool

Carbon Leadership Program

CDP

SBTI

Certificates

SOCIAL Certificates

Business Social Compliance initiative

World Wide Responsible Accredited Production

Social Labor Convergence Program

Supplier Ethical Data Exchange

OUR

Awards &Recognitions

Celebrating our commitment to sustainable innovation.

Leadership in Renewable Energy Integration

Awarded by Citi Birla Group, New Delhi

Victus Apparel Private Limited was given the national recognition by Indian Government for pioneering renewable energy adoption and significantly reducing reliance on fossil fuels across operations.

LEED “Gold” Certified Facility

Victus Apparel Private Limited has been awarded the LEED Gold Rating.